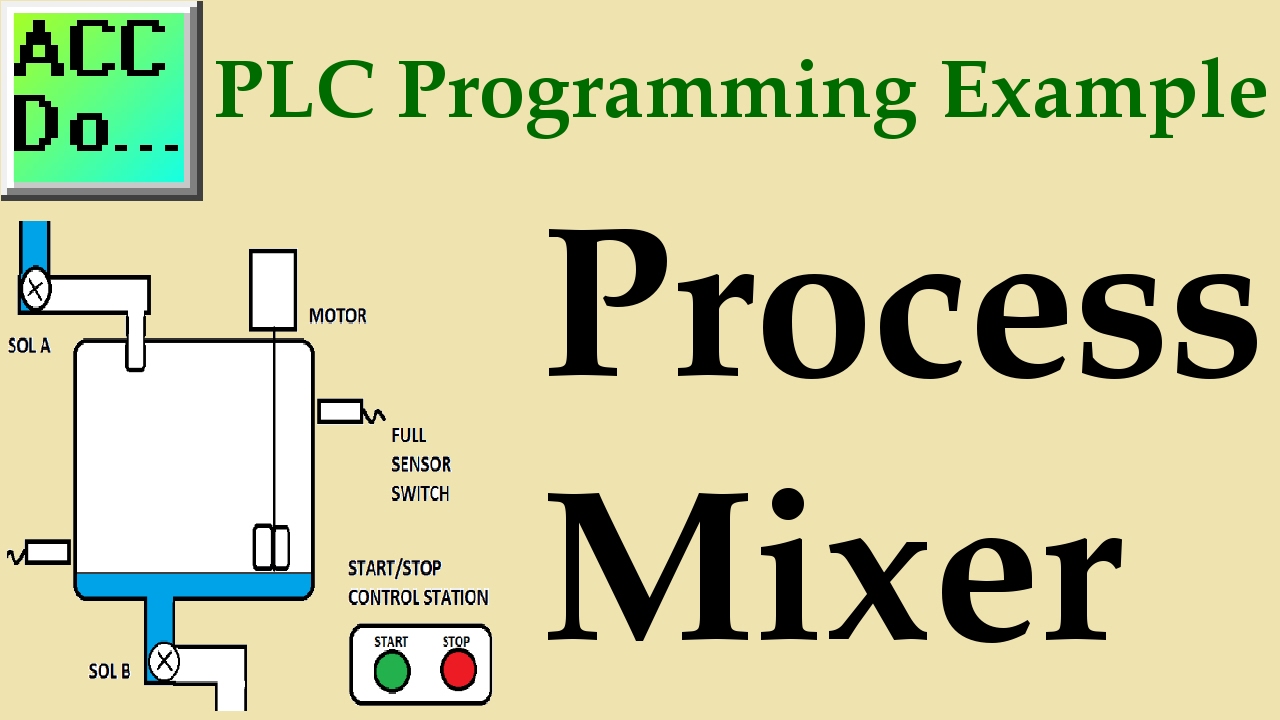

PLC Programming Example Process Mixer ACC Automation

PLC Example Process Mixer Test Simulation YouTube

We will apply the five steps to a PLC programming example process mixer.The process mixer will be programmed using ladder logic. We will discuss each step of.

PLC HMI Tutorials for Mixing Process of a Tank YouTube

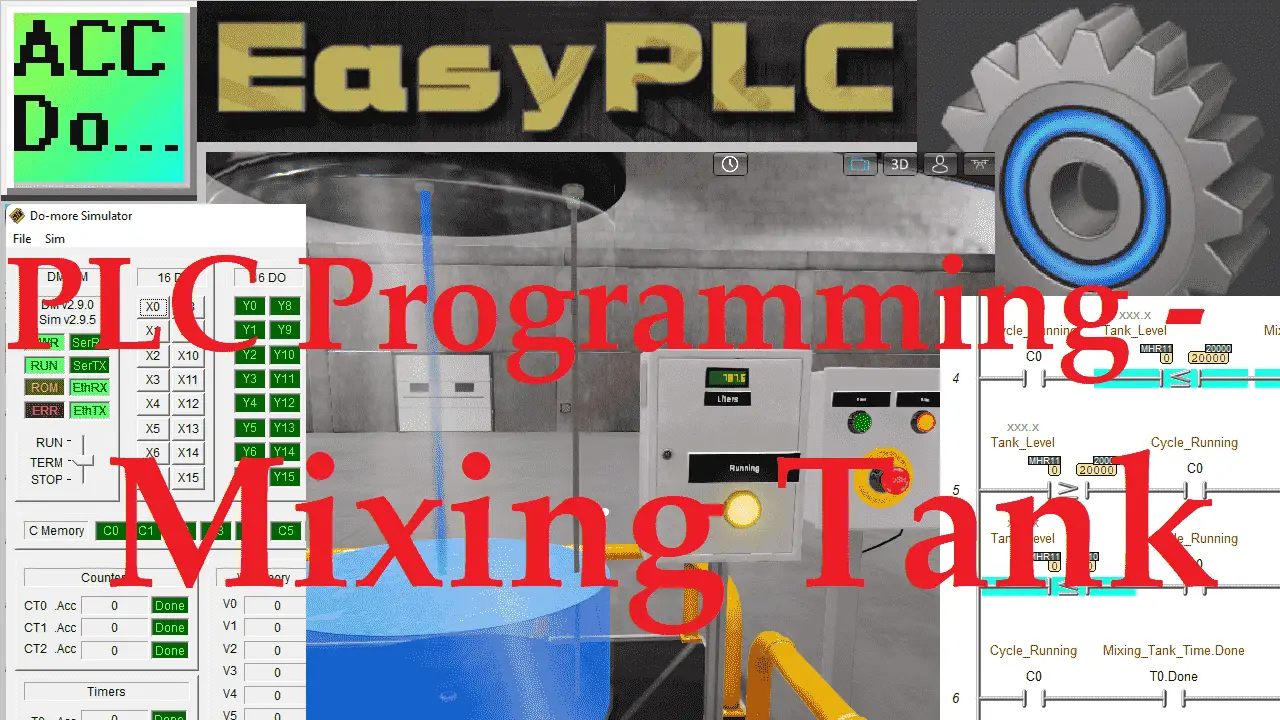

The Machine Simulator (MS) is part of the EasyPLC software suite. It has many built-in machines that are used to show different programming techniques. The i.

PLC Program for Automatic Liquid Mixing Application Mixer PLC Logic

PLC Operation | Mixer Process | Ladder Logic Diagram PLC Operation: To understand the PLC Operation, consider the simple process shown in Fig. 21.63 In this process a mixer motor is to be used to automatically stir the liquid in a vat when the temperature and pressure reach a preset values.

Click PLC EasyPLC PLC Mixer Programming ACC Automation

12 min read · Oct 31, 2022 The Digital Transformation Journey to Industry 4.0 starts by understanding Industry 3.0 Andi Sama — CIO, Sinergi Wahana Gemilang with Cahyati S. Sangaji In Summary -.

PLC Programming Example of a Process Mixer YouTube

In Runge 4, we use timer T4:0 to count the 8 seconds during which the mixer will run, as in Runge 5. After the 8 seconds of mixing, pump P3 is energized to drain the mixed liquid as in runge 6. When you empty the tank, note down till reaching zero level as in Rung 7. At that time, pump P3 will have been stopped.

MIXING PROCESS Basic PLC Programming Training/Tutorial For Beginners

Paul Mueller Company's Pharmaceutical Mixers are the perfect match for all of your sanitary agitation applications. F eaturing more straight-grade 316 stainless steel than virtually any competitive product line, our Mixers provide maximum protection against corrosion and cleaning solutions.. Mueller Top-Mount Mixers with external seals are built for the most stringent sanitary applications.

PLC control system laboratory mixer Products from Dongguan Baopin

PLC Program for Mixing Tank Fig : Mixing tank A tank is used to mix two liquids. The required control circuit operates as follows: A. When the START button is pressed, solenoids A and B energize. This permits the two liquids to begin filling the tank. B. When the tank is filled, the float switch trips.

Stainless Steel PLC Vacuum Emulsifier Mixer Machine 150L Practical

One important PLC. Ease of changing program. Relay circuit change requires physical rewire. Review operation of modified hardwired circuit. PLC requires no rewiring. I/O connections and addressing remain the same. Requires PLC ladder logic program change only. Review PLC modified program.

Click PLC EasyPLC PLC Mixer Programming YouTube

We will apply the five steps to PLC Program development to our following programming example of a process mixer. The process mixer will be programmed using ladder logic. We will discuss each step of the PLC program development. 1 - Define the task: How does the process mixer work? A normally open start and normally. Read more

PLC Mixing Process Ladder and simulation YouTube

Our training courses help you improve your teams' competence, enhance safety, develop your staff's troubleshooting skills, and maximize the availability of your programmable automation controllers (PACs) and programmable logic controllers (PLCs). Register to the country training services portal or select one of the tutorials.

Chemical Mixing Process using PLC PLC Engineering Projects

In a typical mixing tank application, the PLC programmer should expect to have a level sensor, limit switches, position indicators on each valve, metal detectors, reject stations, load cells, and more. However, the purpose of this PLC Programming example is to illustrate the purpose of batching. Therefore, we've omitted a lot of external.

PLC Programmable Control Plastic Material Mixer Machine High Speed SRL

Keywords- PLC,SCADA,Sensors,Automation I. INTRODUCTION In this paper we are using PLC to control the Industrial Mixer. Programmable Logic Controller (PLC) is a small computer used for automation of real-world processes, such as control of machinery on factory assembly lines. The PLC usually uses a microprocessor.

Click PLC EasyPLC PLC Mixer Programming ACC Automation

Also consider one level switch for empty level detection. For controlling the level we can use single acting valve (fully open and fully close type). For mixing, agitator is used and it is connected with motor shaft. Heater and temperature sensor are installed inside the tank. Here materials are mixed until it reaches the set point of.

PLC Program for Automatic Liquid Mixing Application Mixer Logic

The Click PLC will be used to program this virtual 3D mixer machine. A DRUM instruction will be used in the PLC for the sequencing. Using the Click Plus PLC, we will connect to the mixing machine. This will be done using Modbus TCP (Ethernet) for communications. Using the five steps for program development we will show how this is programmed.

PLC programming tutorial for beginners in automated Color mixing

We applied the five steps to a PLC programming example process mixer.The process mixer ladder logic program will now be tested. This test simulation will be.

PLC Programming Mixing Tank EasyPLC / DoMore ACC Automation

In this video, you will learn the PLC HMI tutorials for a mixing process of a tank using ladder logic programming and graphics design.# Free PLC and SCADA Tr.